WHAT TO CHECK ON HATCH COVERS

Guide Notes for Hatch Covers of Dry Cargo Ships Survey

1.

Statutory surveys of hatchcovers and their coamings are to be carried

out by the Administration as part of the annual survey required by

article 14 of the International Convention on Load Lines, 1966, as

modified by the 1988 Protocol relating thereto. The International

Maritime Organization (IMO) adopts the International Code on the

Enhanced Program of Inspections During Surveys for Bulk Carriers and Oil

Tankers, 2011 (2011 ESP Code) by means of the Resolution A. 1049 (27)

regarding IMO mandatory inspection regime for tankers and bulk carriers

which contains the approved text as set out in the annex to this

Resolution.

2.

A thorough survey of hatch covers and coamings is only possible by

examination in the open as well as closed positions and should include

verification of proper opening and closing operation.

As

a result, at least 50% of hatch cover sets should be surveyed open,

closed and in operation to the full extent in each direction, at each

annual survey. The closing of the covers should include the fastening of

all peripheral, and cross joint cleats or other securing devices.

Particular attention should be paid to the condition of hatch covers in

the forward 25% of the ship’s length, where sea loads are normally

greatest.

3.

If there are indications of difficulty in operating and securing hatch

covers, additional sets above those required by 2, at the discretion of

the surveyor, should be tested in operation.

4.

Owners and operators should ensure that facilities and personnel are

available to perform the required hatch cover movements during each

annual survey.

5.

It is implicit that if the hatch securing system cannot be properly

operated, the ship will be obliged to effect repairs under the

supervision of the Administration. Where hatch covers or coamings

undergo substantial repairs, the strength of securing devices should

comply with IACS UR S30.

6.

Owners and operators should be made aware that partial replacements in

cleating systems have the potential to introduce imbalance between old

and new cleats. This could result in isolated cleats being subjected to

excessive loads, which may then lead to sequential failure.

7. For each hatch cover set, at each annual survey, the following items should be surveyed:

7.1

cover panels, including side plates, and stiffener attachments of

opened covers, by close up survey (for corrosion, cracks, deformation);

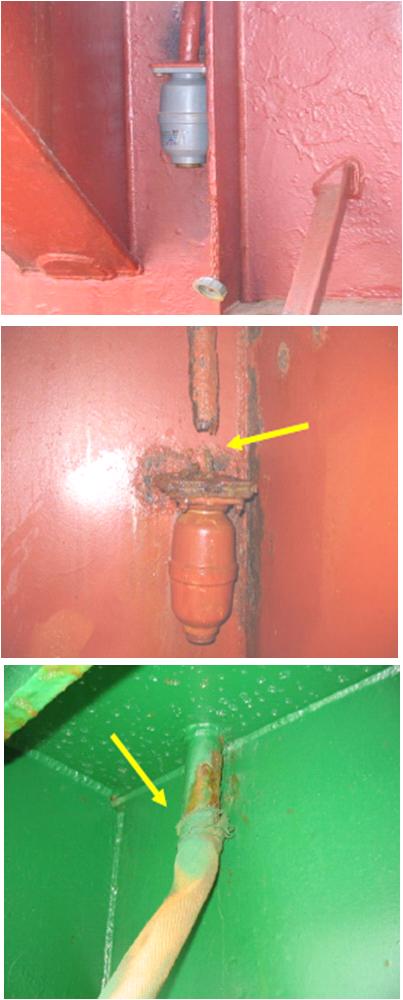

7.2

sealing arrangements of perimeter and cross joints (gaskets for

condition and permanent deformation, flexible seals on combination

carriers, gasket lips, compression bars, drainage channels and non

return valves);

7.3 clamping devices, retaining bars, cleating (for wastage, adjustment, and condition of rubber components);

7.4 closed cover locating devices (for distortion and attachment);

7.5 chain or rope pulleys;

7.6 guides;

7.7 guide rails and track wheels;

7.8 stoppers;

7.9 wires, chains, tensioners and gypsies;

7.10 hydraulic system, electrical safety devices and interlocks; and

7.11 end and inter-panel hinges pins and stools where fitted.

8.

At each hatchway, at each annual survey, the coamings, with plating,

stiffeners and brackets should be checked for corrosion, cracks and

deformation, especially of the coaming tops.

9.

Where considered necessary, the effectiveness of sealing arrangements

may be proved by hose or chalk testing supplemented by dimensional

measurements of seal compressing components.

http://www.iacs.org.uk/document/public/Publications/Guidelines_and_recommendations/PDF/REC_15_pdf178.pdf

Resolution A. 1049 (27)

http://www.imo.org/KnowledgeCentre/IndexofIMOResolutions/Documents/A%20-%20Assembly/1049%2827%29.pdf

Comments

Post a Comment